This CNC pipe cutting machine can realize auto program and auto CNC nesting work for any complicated joint type of intertube, pipe, etc. and can cut any type welding bevel at one time.

II.Pipe/Tube Cutting Machine Video

III.The Details Show

CNC Round Pipe/Tube Plasma Cutting Machine is special CNC equipment which is used for cutting metal pipe automatically. cnc plasma tube cutting machine can realize auto program and auto CNC nesting work for any complicated joint type of intertube, pipe, etc. and can cut any type welding bevel at one time.

KR-XF5 CNC Pipe Profile Cutting Machine is a device that automatically calculates and cuts off the end of the steel pipe joints; it does not require operator programming (simple library programming does not require professional designer docking, simple and easy to understand), only need to input the matched diameter of pipe, intersection angle parameters, the machine will automatically cut out the pipe intersecting lines and intersecting holes, and welding groove, it does not need manual polishing.Widely used in the cutting and processing of pipeline structural parts in shipbuilding, construction, petrochemical, machinery, metallurgy and other industries.

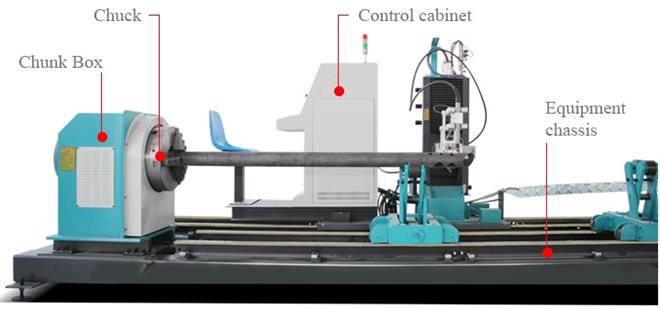

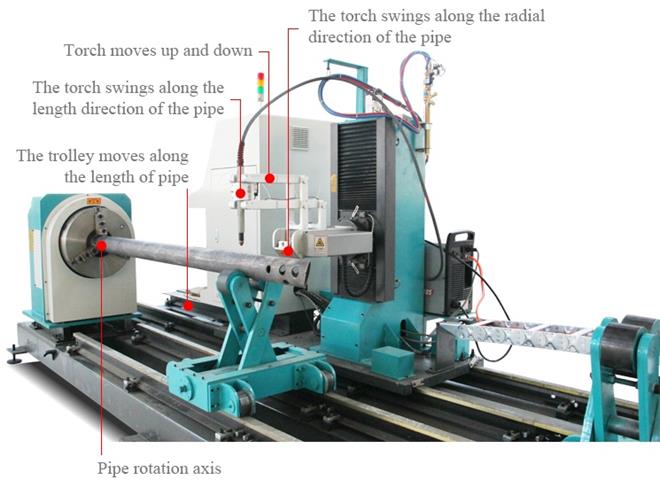

This machine is designed as a horizontal structure, mainly including base (square tube welding chassis), pipe rotating mechanism (three-jaw chuck and Y-axis rotating power device), steel pipe support bracket (4 groups of scissor shape brackets ), torch moving mechanism, torch lifting mechanism, torch deflection mechanism (the parallelogram structure material is manufactured by aeronautical aluminum CNC machining center), walking track (high-precision machining 24KG guide rail as the transmission component of trolley), electrical control system, etc.

The Details Show

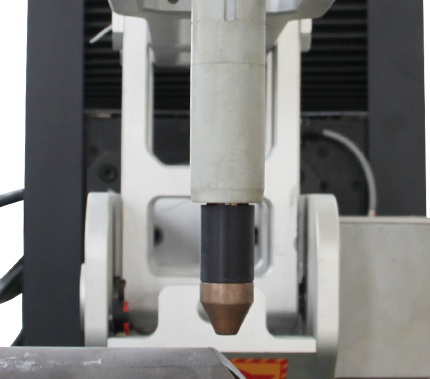

1. CUTTING ARM

Aeronautical aluminum materialresistnt to high temperature and pressure. Any graphics can be cut on the pipe, beveled, and intersecting nodes can be cut.

2.HEADSTOCK

The steel plate tailor-welded box structure design is adopted,and the structure is compact to improve the overall rigdity and strength.

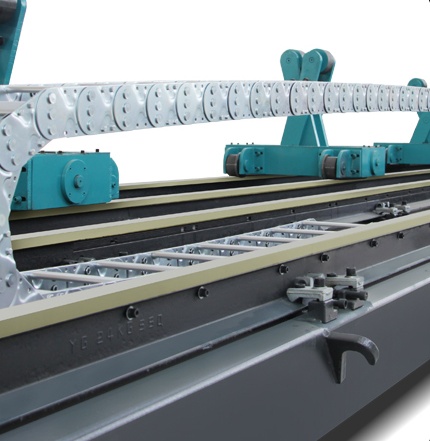

3.24KG RAIL

The top surface and two side surfaces are precisely processed by a CNC grinder using 24KG grade 55Q ground rails to ensure the leveland parallelism of the moving torch.

4.ADVANCED SYSTEM

The system uses Pro-face SGP-2301HL handheld graphical operation intertace.lt has world-class safety protection functios:3-position enadle switch

The Product Parameters

Technical Parameters | |

Cutting pipe diameter | 50~630mm or 60~800mm |

Cutting range | 6M,9M,12M(length can be customized) |

Cutting mode | Plasma and flame(oxy-fuel) |

Control system | Advantech IPC with PIP |

Programming Software | Curve library, Tekla, AuotoCAD |

Driving system | Japan Panasonic Servo Motor |

Cutting speed | 10~2000mm/min |

Travelling speed | 10~6000mm/min |

The axial swing Angle of the cutting torch | α=±60° |

The Radial swing Angle of cutting torch | β=±55° |

Cutting length accuracy | ±1.5mm |

Oblique crossing angel | 15°-170° |

Angle error | ±1° Plasma Air , Flame Oxygen+Acetylene /propane |

Bevel angle | plasma cutting<=±45° flame cutting<=±60° |

Motion range of host axis

Y Axis: Pipe rotation driving axis

360°free rotation, Japanese Panasonic 3000W servo motor,the driving system is driven by a precision gear box and gear pair, the speed is 0.01-8r/min, and the positioning accuracy is ±0.2°

X Axis:Torch move along pipe axial direction

The max stroke is 12000mm,Japanese Panasonic 750W servo motor,the driving system is driven by precision gearbox, gear and rack, positioning accuracy ±0.2°

Z Axis:Torch lifting (The axis does not participate in linkage)

Max stroke 335mm,Japanese Panasonic 750W servo motor,the driving system is driven by precision gear box and ball screw, positioning accuracy ±0.2°

B Axis:Torch move along pipe axial direction

swing±60°,Japanese Panasonic 400W servo motor,the driving system is driven by a precision gearbox, positioning accuracy ±0.2°

A Axis:Torch move along pipe radial direction

Pendulum angle±55°,Japanese Panasonic 400W servo motor,the driving system is driven by precision gear box,positioning accuracy ±0.2°

Cutting Sample

Customer Site

Corporate Headquarters:

2477 Qizhou Road, Jinan, P.R.China