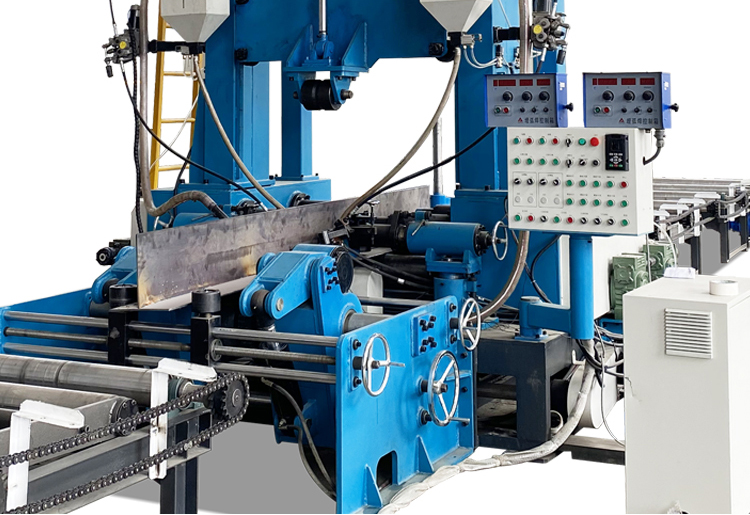

H Beam Assembly Machine is suitable for H -shaped steel with symmetrical and equivalent sections.

Features

★ It is suitable for H -shaped steel with symmetrical and equivalent sections.

★ Enter the three groups of the S -S -S -group of the Roller Paths to the Middle Robot Group's wing plates and abdomen plates to the host, and the hydraulic cylinder driver the synchronous clamping between the two sides to automatically implement the middle device. Essence

★ Control the entire form of welding and fast -forwarding speed, weld length and interval length by PLC control, and high efficiency in operation and establishment

Product Parameters

| Model: | ZL-0818 | ZL-1020 |

| Height of the abdomen: | 200-1800mm | 200-2000mm |

| The thickness of the abdomen: | 6-32mm | 6-60mm |

| Wings width: | 200-800mm | 200-1000mm |

| Wing plate thickness: | 6-40mm | 6-80mm |

| Workpiece length: | 500-6500mm/min | 4000-15000mm/min |

| Power: | 8.4kw(excluding two welding machines) | 15kw(excluding two welding machines) |

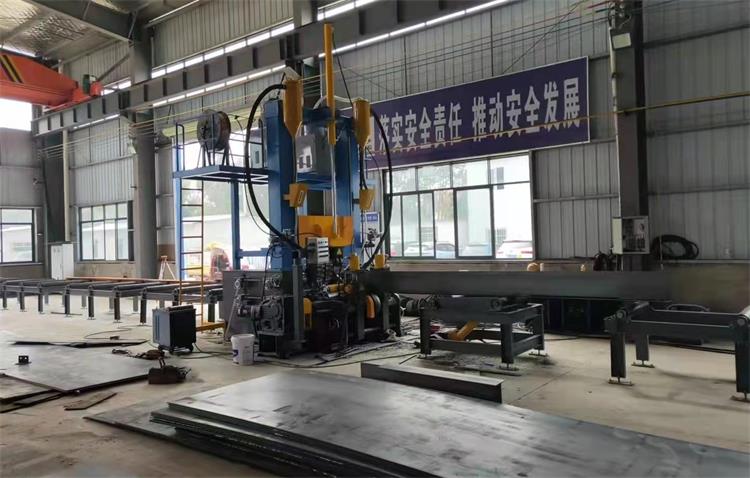

The machine is a special equipment for assembling, welding, and straightening H beam, I beam and conical I Beam.It integrates the processes completed by the three machines of assembly machine, gantry welding and straightening machine into one machine, which significantly improves production efficiency,reduces, equipment costs, saves equipment installation space, and it is the most efficient production equipment for H-beam and T-beam.

Main machine power | 13.4 kw |

Web plate height | 200 to 2000 mm |

Web plate thickness | 6 to 14 mm |

Straightening speed | 0.35-3 m/min |

Flange plate width | 200 to 800 mm |

Flange plate thickness | 6 to 20 mm |

Minimum Order Quantity | 1 Unit |

Above are our standard model, it can be designed and manufactured according to customer’s request.

Product Description

Due to our proficiency of this field, we are engaged in presenting H Beam Assembly Machine. We are presenting these products to customers within given time-frame.

Details:

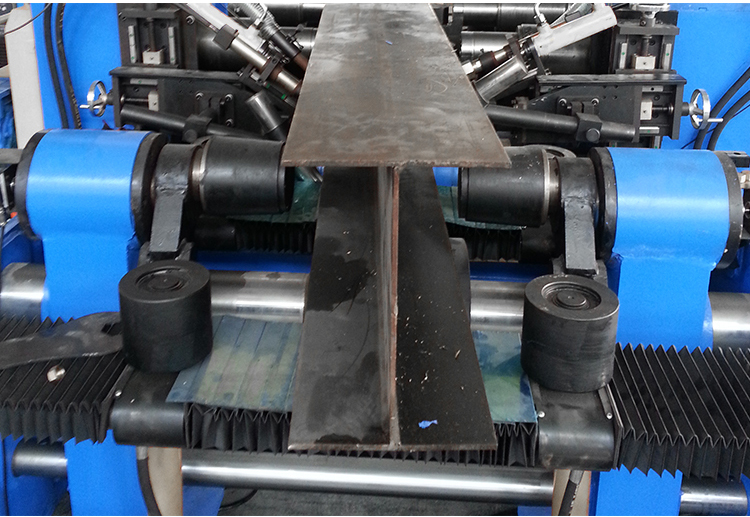

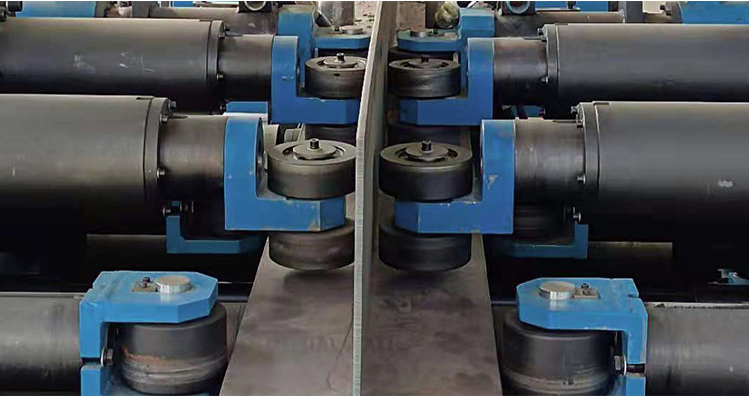

· Our offered H-Beam Assembling Machine comes with clamping of the flange and the web that adopts hydraulic automatic centering and has larger suitable ranges for best performance to price ratio. Furthermore, these offers better positioning accuracy by means of multi groups of guiding roller and eliminate the fishtailing phenomenon. This carriage can complete the fillet welding by weaving the torch when it reaches the blind zone after the carriage stops traveling and benefits from the high-performance magnet, profiling caster, and four-wheel drive mode, and finally achieves reliable traveling.

1.Various kinds of welding type, it can use single arc single wire welding or single arc double wire welding according to users’requirement; it uses submerged arc welding.

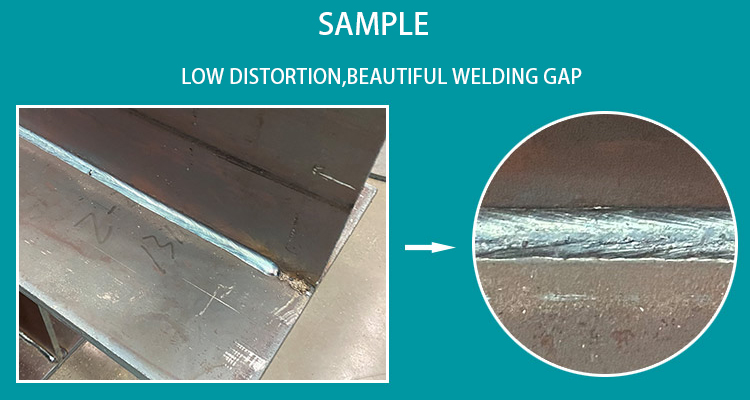

2.Double-wire flat fillet welding is used to weld on both sides at the same time, with small deformation and improved efficiency.

3.Flange Straightening Part,Correction of the auxiliary transmission idler mechanism, the left and right clamping mechanism of flange

4.PARAMETRIC INTERFACE

Using parameterized interface, it is convenient to adjust processing specifications and various public parameters

Features:

· Control system is based on MCU for easy operation and stable performance

· Light in weight

· Outstanding performance

Performance and characteristic:

· The main assembling machine adopts heavy duty assembling structure which has applied invention patent, web plate and flange plate centering and positioning automatically, to make the assembling precision and efficiency greatly improved.

· Firm welding torch fix mechanism is set up separately, it not only can adjust the height and horizontal moving position, also can adjust the angle of the welding torch in two directions, it guarantees the nice seam form.

· Assistant straightening machine has special designed structure, the two straightening rollers can straighten workpiece automatically under the pushing of oil cylinder, straightening mechanism will not block the line of sight on the seam, it is convenient to see the adjustment of the welding torch and seam quality.

· Assembling machine and assist straightening machine can be discharged and work separately.

· Assistant straightening machine can work as small straightening machine after the refit.

Our Advantages

(1) Small floor space

H beam traditional welding production line: the production area is more than 4500 square meters;

Yomi H/T steel assembly welding and straightening machine: the production area is more than 270 square meters, equivalent to the area occupied by a assembly machine;

(2) Reduced labor costs

H beam traditional welding production line :1 set assembly machine, 2 sets gantry welding machines, 1 set straightening machine,total 3 sets of equipment, the continuous production personnel operation of 5-6 people (2 people of assembly machine, 2 people gantry welding machines, 1-2 people straightening machines);

Yomi H/T steel assembly welding straightening machine: personnel operation for 1-2 people;

(3) High qualified rate

H beam traditional welding production line: the qualified rate of production is about 30%;

Yomi H/T steel assembly welding straightening machine: according to the customer said production pass rate of about 90%;

(4) Low power consumption

H beam traditional welding production line :(1 assembly machine, 2 gantry welding machine, 1 straightening machine) the total power is about 250KW, calculated by working 10 hours a day, the coefficient is about 0.8. The electricity consumption is about 2000 degrees/day.

Yomi H/T steel assembly welding straightening machine: The total power is 125KW, calculated by working 10 hours a day, the coefficient is about 0.8, and the electricity consumption is about 1000 degrees/day;

(5) Without welding arc plate

H beam traditional welding production line: the traditional production line needs to add arc plate, calculated according to the annual output of 10,000 tons, the arc plate generated by the material, welding (wire) connection, grinding (piece), labor, etc., is expected to cost about 300,000 yuan;

Yomi H/T steel assembly welding straightening machine: skilled operation, without arc plate welding head;

(6) Reduce rotating times, high production efficiency

H beam traditional welding production line: traditional production line (1 assembly machine, 2 gantry welding machine, 1 straightening machine), each H beam lifting about 8 times (assembly 4 times,gantry welding 4 times, straightening many times), waste time, efficiency is greatly reduced:

Yomi H/T steel assembly welding and straightening machine: the production efficiency is higher than the traditional production line (1 assembly machine, 2 gantry welding machine, 1 straightening machine), reduce the lifting times, only need 2 times;

(7) Save hoist driving

H beam traditional welding production line: about 4 hoist driving are needed, resulting in fighting or insufficient driving;

Yomi H/T steel assembly welding straightening machine: use 1 hoist driving, save 3 hoist driving;

(8) Advanced equipment for the production of t-beam one-time forming in the industry

H beam traditional welding production line :T beam is the use of H beam in the center of the web with plasma or flame and other equipment hot cutting, cutting process deformation, difficult to correct, the rejection rate is very high, resulting in high cost;

Yomi H/T assembly welding straightening machine: a molding without two times, save more materials, for enterprises to create higher benefits:

(10) Different straightening methods and times

H beam traditional welding production line: it belongs to cold straightening, multiple straightening, about 15mm/ time, for example, 16mm flange, need straightening about 10 times;

Yomi H/T steel assembly welding straightening machine: belongs to heat straightening, forming at one time;

(11) Different straightening thickness

H beam traditional welding production line: 40 straightening machine is used in general industry, which belongs to cold straightening. The maximum thickness of straightening flange is 18mm-20mm.

Yomi H/T steel assembly welding straightening machine: belongs to the heat straightening, straightening thickness 40mm;

(12) Automatic model adjustment

H beam traditional welding production line: the flange and web need to be manually adjusted when the assembly machine and the straightening machine work, which wastes time. For example, when the assembly machine works, the equipment needs to be adjusted when H beam of different specifications is replaced every time, and the normal skilled operators also need about half an hour.

Yomi H/T steel assembly welding straightening machine: automatic model adjustment, web, flange automatic reference alignment, convenient and fast;

(13) High melting depth

H beam traditional welding production line: web 14mm or more need to bevel;

H/T steel assembly welding straightening machine: it belongs to hot welding, the company promises that the web below 20mm is free of groove welding;

(14) Workpiece walking

H beam traditional welding production line :(gantry welding) for equipment walking, need to be removed from the equipment into the component before welding, efficiency reduced;

H/T steel assembly welding straightening machine: workpiece walking, equipment fixed, equipment continuous work, workpiece uninterrupted welding, efficiency increased by about 20%;

(15) Investment expenses

H beam traditional welding production line: need to purchase gantry welding guide rail, welding cable, W frame and so on, about 8000$ dollars;

H/T steel assembly welding straightening machine: access to the power supply can be used, no extra cost, convenient and fast, cost saving;

Customer Site Display

T/H Beam assembling, welding, and straightening three in one Machine

Corporate Headquarters:

2477 Qizhou Road, Jinan, P.R.China