H Beam plasma cutting machine,it transports profiles to cutting station by conveying rollers, and it can cut H beam, I beam, channel steel, and angle steel to realize thermal cutting processing for profile intersecting.

H Beam plasma cutting machine,It transports profiles to cutting station by conveying rollers, and it can cut H beam, I beam, channel steel, and angle steel to realize thermal cutting processing for profile intersecting.

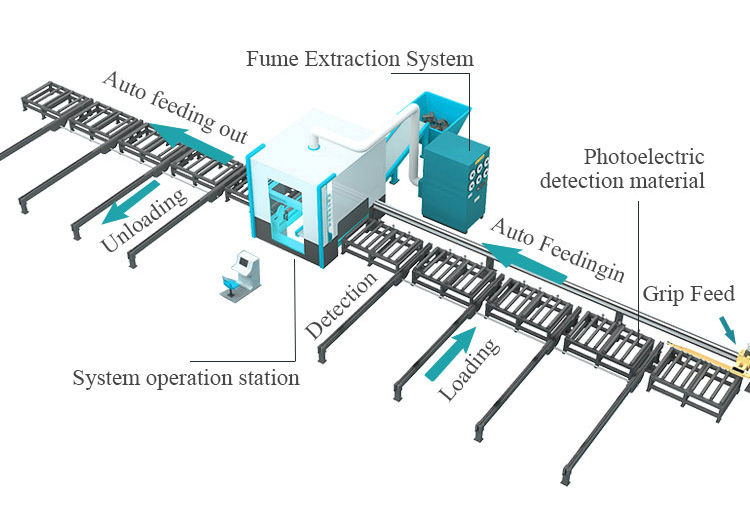

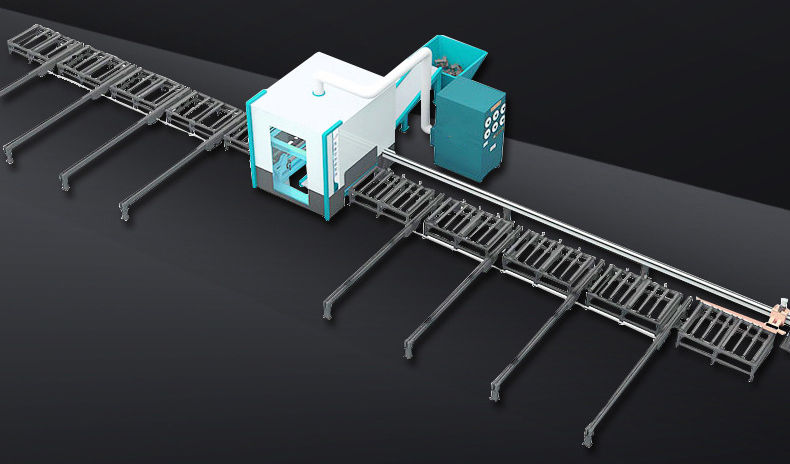

◆Application:Profile Plasma Cutting Machine is consisted of cutting unit, roller frame,feeding trolley and rail, finished profile conveying station. It is a hot cutting processing equipment for H beam, I beam, Channel steel, Angle steel, bulb flat and their inter-sectioning shape.

◆Dimension: The whole cutting machine is 28000mm length, of which cutting unit length is 2000mm, conveying unit is 14000mm, the max cutting materials is 12000mm.

2.1.Main Technical Parameters:

Working area | Name | Parameters | |

H beam/I beam/Channel steel/angle steel | 200mm-1250mm | ||

Cutting method | Plasma/Flame | ||

Effective cutting length | 12m | ||

Profile cutting form | Fixed length straight cut, fixed length oblique cut and end socket function | ||

Applicable materials | Carbon structural steel, stainless steel | ||

Cutting method | Plasma power source | Herpertherm XPR300A | |

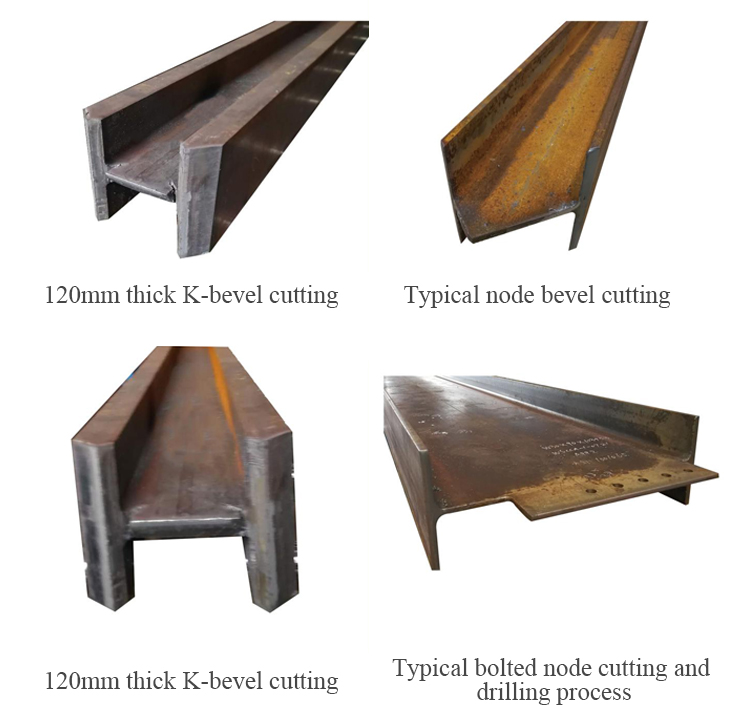

Plasma cutting thickness | Pierce cutting thickness 1-45mm | ||

Oxy fuel cutting thickness | Vertical cutting thickness ≤60mm | ||

Beveling cutting | ±45° | ||

Machine accuracy | Cutting precision in length | ±1.5mm | |

Cutting sharp | According to confirmed drawing( offered when signing technical contract) | ||

Cutting speed | 10~2000mm/min | ||

Moving speed | 10~6000 mm/min | ||

Cutting accuracy execution standard | ISO9013-2002\ISO8206-1991\ JB/T10045.4-1999JB | ||

Axis | Robot axis | X Axis:the cutting torch movement left and right | |

Y1 Axis&Y2 Axis: True bilateral synchronization axis:the cutting torch movement forward and back | |||

A Axis:the cutting torch rotation | |||

B Axis:the cutting torch yawing | |||

C Axis:the external workpiece is to the horizontal feeding | |||

Z Axis:the cutting torch up and down | |||

Weight | Maximum profile weight to be cut | 5000Kg | Note:Can customized according to offered max weight |

2.2.Cutting Efficiency Measurement

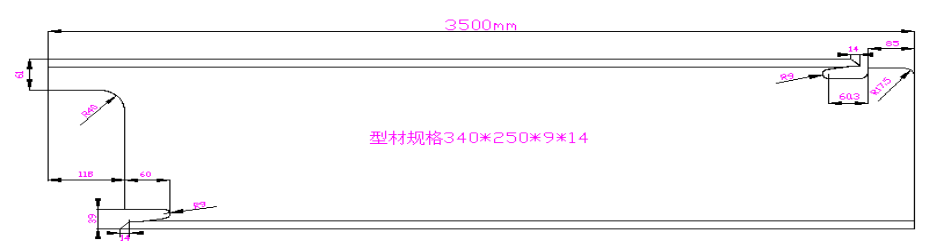

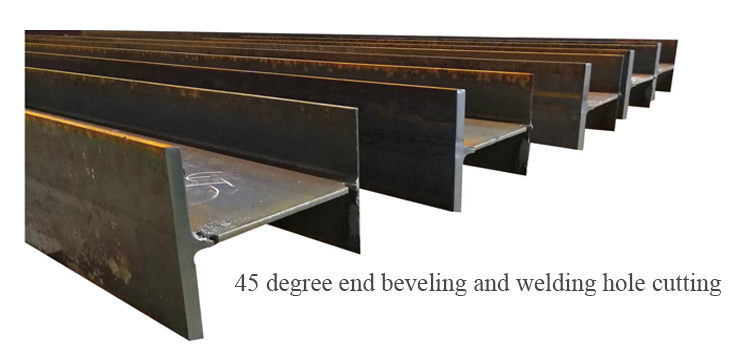

Profile specifications 340*250 as below drawing.( Max cutting length 3500mm. The main cutting process includes single and double-sided beveling, over-welded hole and web shaped track)

Adopt hypertherm XPR300 fine plasma power source 170A current, Process No. 1152 Air + Oxygen

Provides stable source pressure and flow (air + oxygen) on site

Cutting result record:

Single structural profile cutting time is 8 minutes.

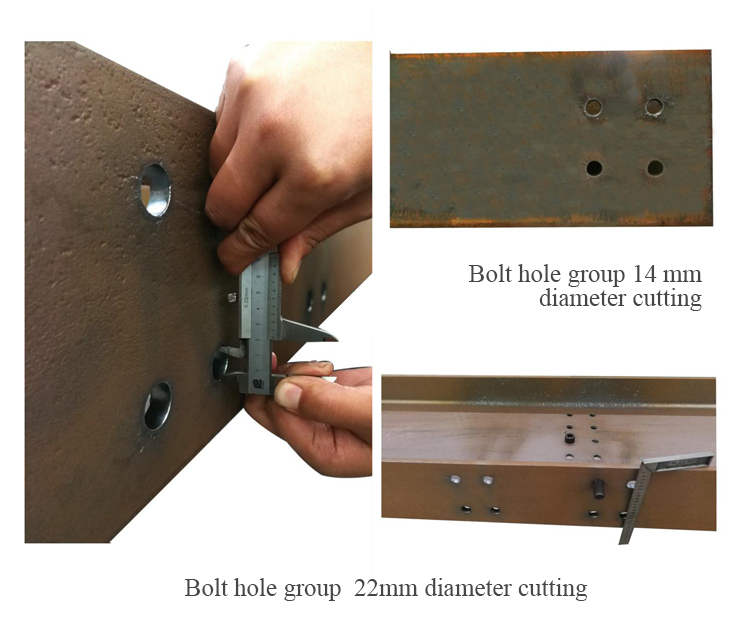

The distance between the two over-welded holes is 6-8 mm.

Our Advantages

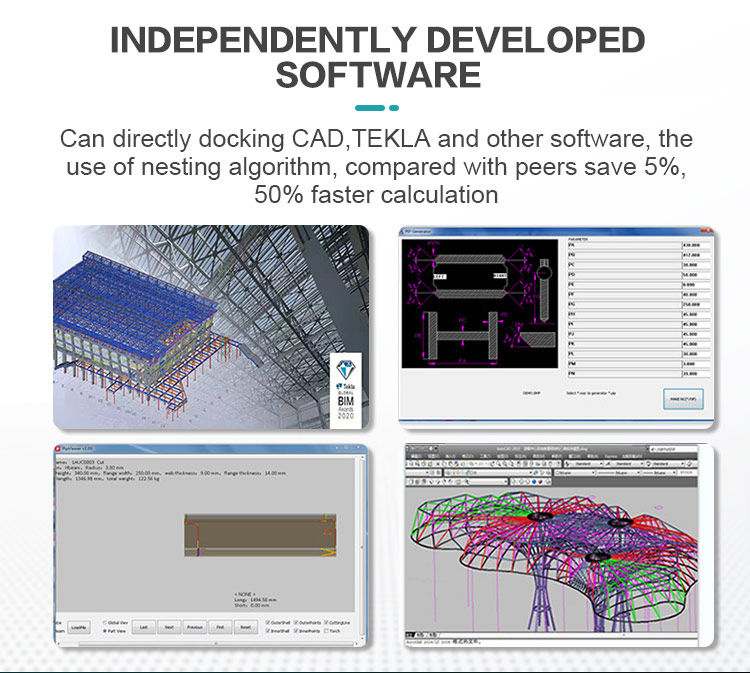

INDEPENDENTLY DEVELOPED SOFTWARE

Can directly docking CAD,TEKLA and other software,the use of nesting algorithm,compared with peers save 5%,50% faster calculation.

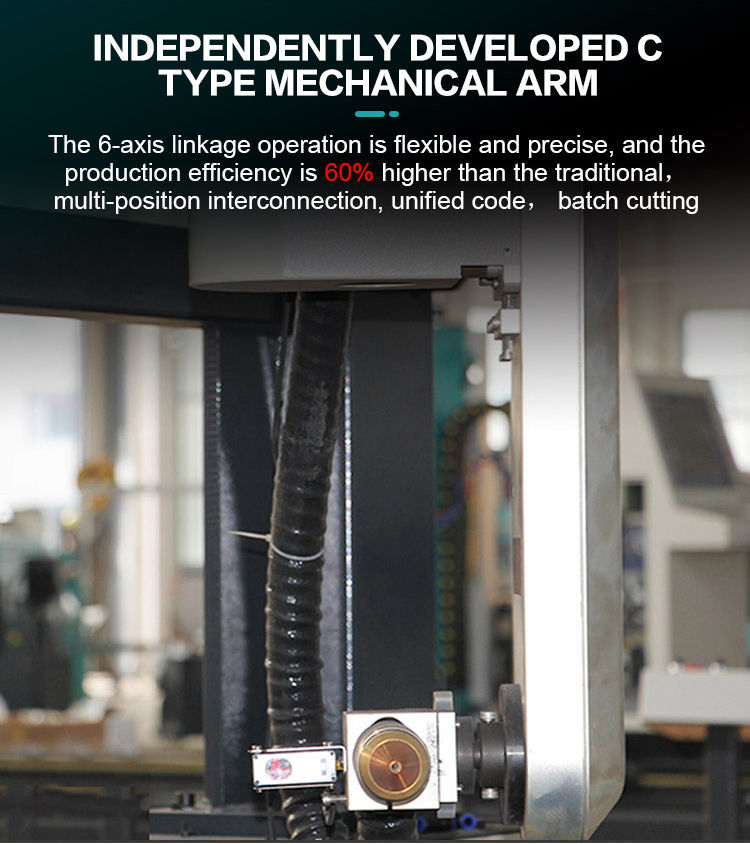

INDEPENDENTLY DEVEL OPED C TYPE MECHANICAL ARM

The 6-axis linkeage operation is flexible and precise,and the production efficiency is 60% higher than the traditional,multi-position interconnection,unified code,batch cutting.

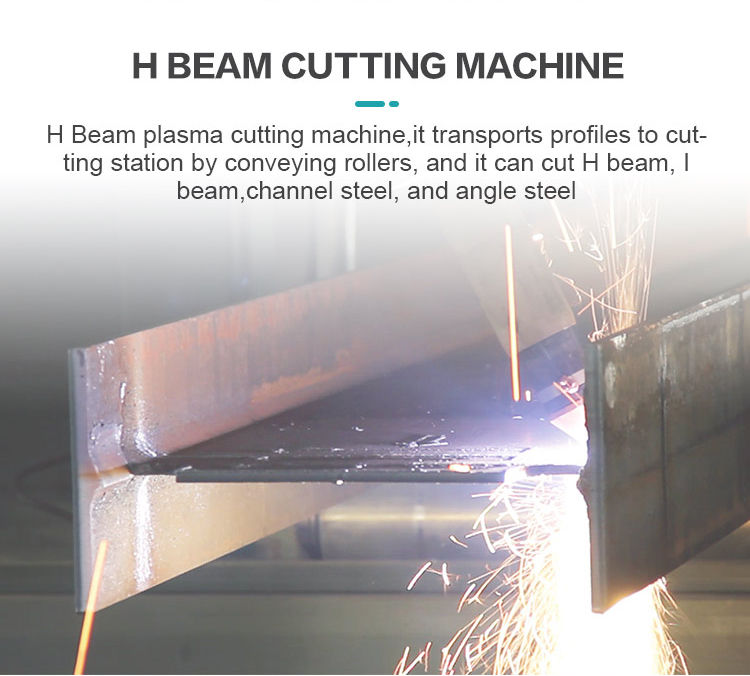

H BEAM CUTTING MACHINE

H Beam plasma cutting machine,it rransports proofiles to cutting station by conveying rollers,and it can cut H beam,I beam,chnnel steel,and angle steel

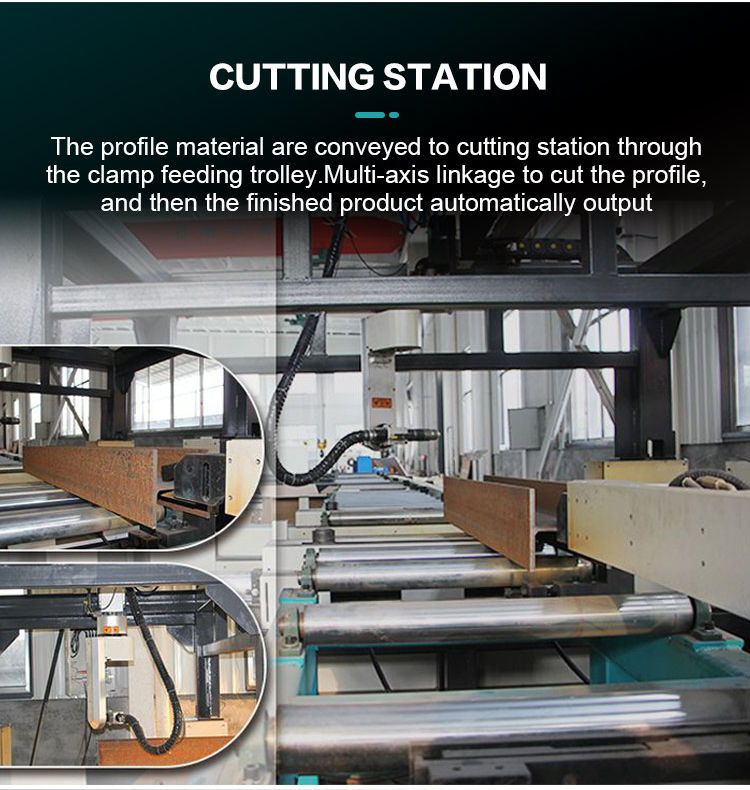

CUTTING STATION

The profile material are conveyed to cutting station through the clamp feeding trolley.Multi-axis linkage to cut the profile,and then the finished product automatically output.

Model | H beam cutting Machine |

H beam | 100-800mm |

Effective cutting length | 12000mm |

Cutting length deviation | ±1.5mm |

Bevel cutting | ±45° |

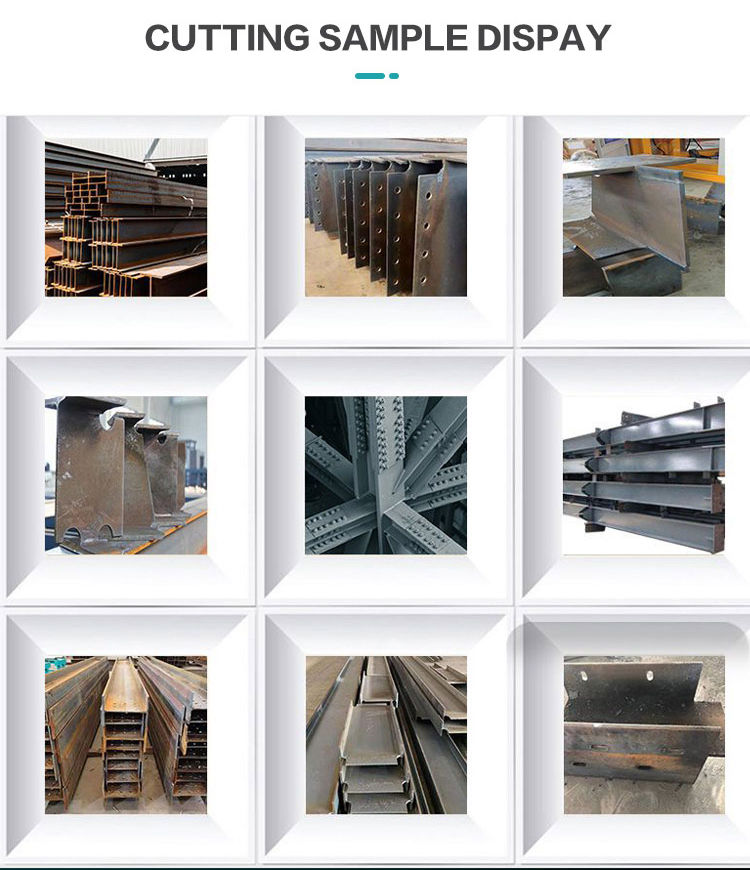

Workpiece cutting process | Cut any shape and cut hole in flange side and web side |

Cutting method | Plasma and flame |

Plasma power | Hypertherm |

Flame cutting thickness | 6-60mm |

Computer | Taiwan Advantech Industrial Computer |

Driving motor | Servo motor |

Software | Auto profile |

Load | 5t |

Weight and size | |

Size | Can be customized according to your factory space |

Shipping | Two 40ft containers |

Weight | 17T |

Working condition | |

Working pressure of compressed gas | Above 7mpa |

Require gas flow of plasma | 4500L/H |

Working environment | Ventilation , no concussion |

The acceptable temperature around | -20℃ -50℃ |

Voltage | Machine :220/380V ,50/60HZ |

Power wattage | 5KW |

Types of gas | Plasma :Air , Flame :Oxygen+Acetylene /propane |

Customer Site

Corporate Headquarters:

2477 Qizhou Road, Jinan, P.R.China