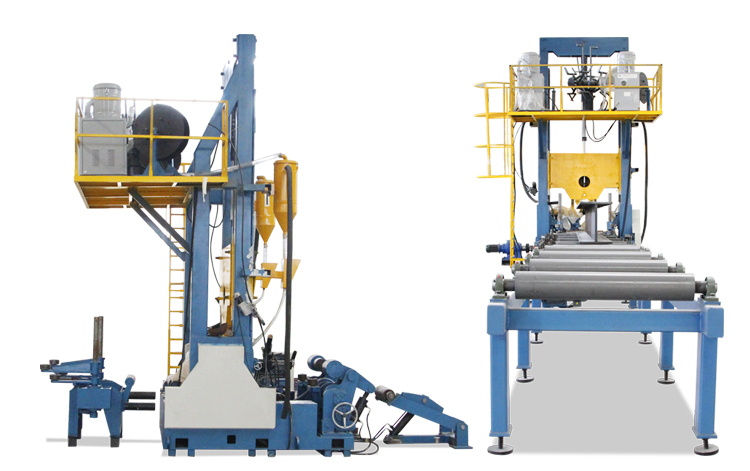

3 In 1 Manufacturer Producer H Beam Welding Line H beam cnc assembling welding straightening machine is a special equipment for directly assembling, welding and straightening the flange plate and web plate of H beam

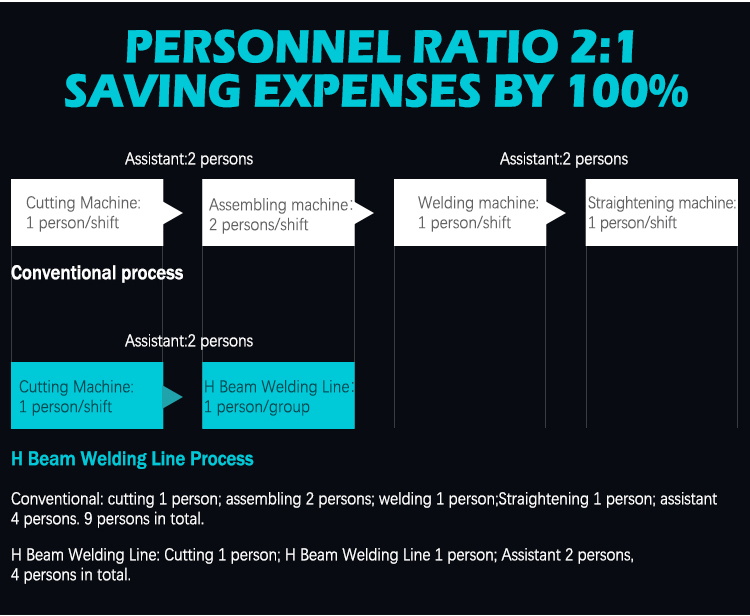

3 In 1 Manufacturer Producer H Beam Welding Line H beam cnc assembling welding straightening machine is a special equipment for assembling, welding, and straightening H beam, I beam and conical I Beam.It integrates the processes completed by the three machines of assembly machine, gantry welding and straightening machine into one machine, which significantly improves production efficiency,reduces, equipment costs, saves equipment installation space, and it is the most efficient production equipment for H-beam and T-beam.

The Details Show

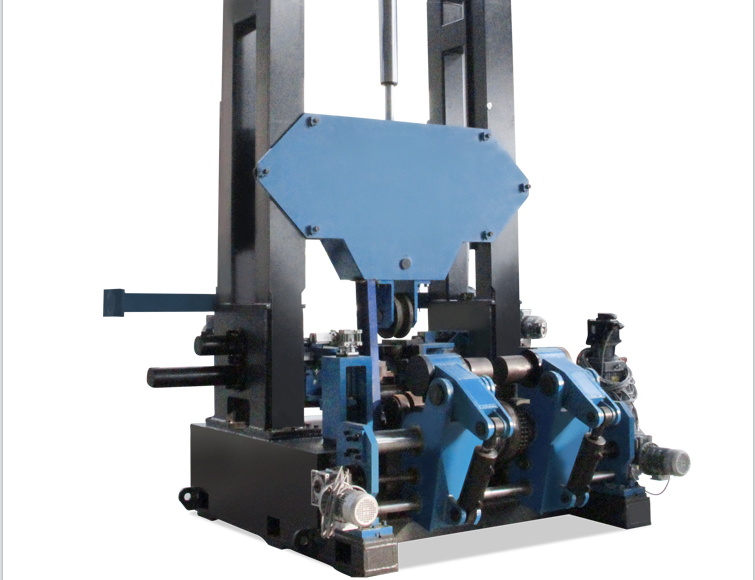

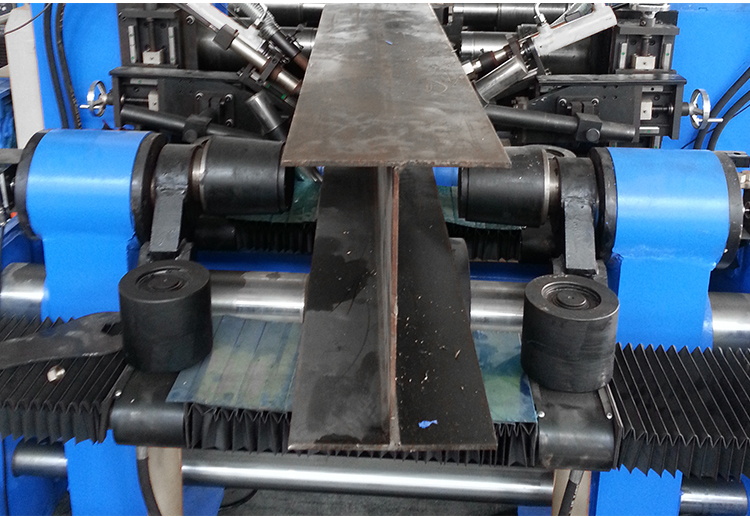

1. Assembly Parts

Main driving roller power components, upper mast pressing device, web clamping device, flange clamping device, hydraulic alignment device, etc

2.Hydraulic system assembly

The hydraulic system mainly includes: hydraulic pump station, lever centering cylinder, compaction cylinder, wing positioning cylinder,web positioning cylinder, correction pressing cylinder, and glued hose

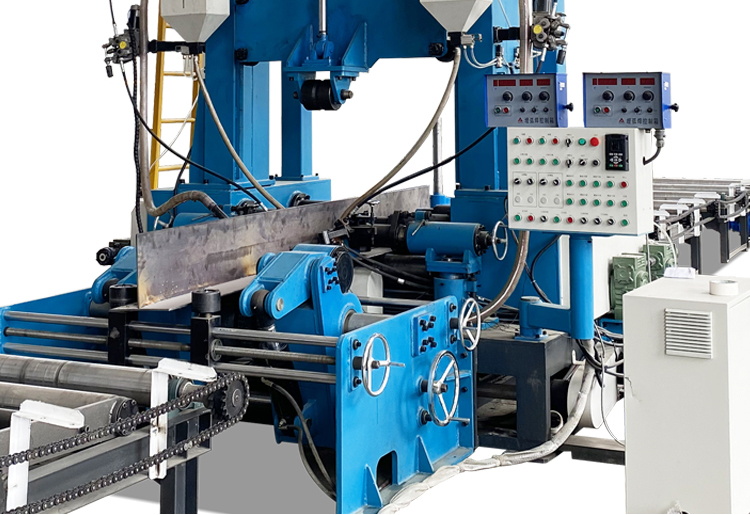

3.Welding Part

Composed of up and down adjustment mechanism of double wire welding torch, tilt tracking mechanism of welding torch, clamping mechanism, automatic flux recovery and conveying , submerged arc welding machine, etc

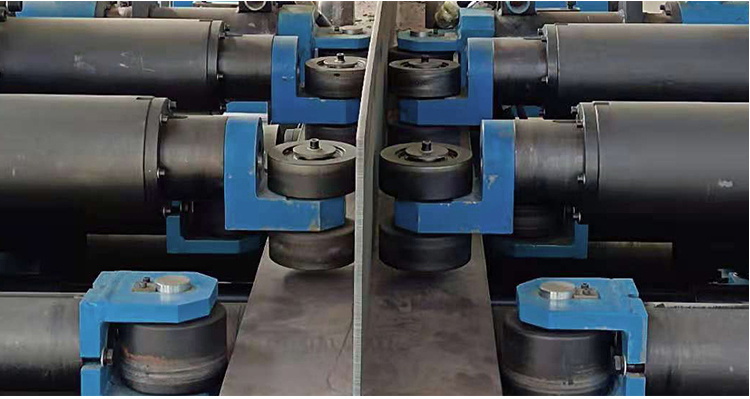

4.BILATERAL WELDING

Double-wire flat fillet welding is used to weld on both sides at the same time, with small deformation and improved efficiency

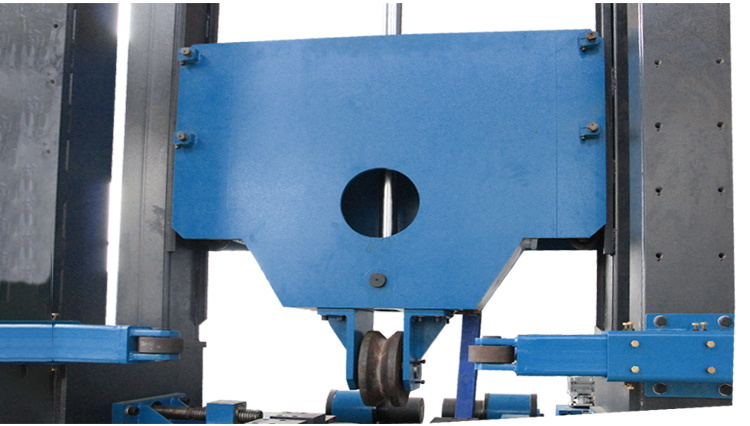

5.Flange Straightening Part

Correction of the auxiliary transmission idler mechanism, the left and right clamping mechanism of flange

6.PARAMETRIC INTERFACE

Using parameterized interface, it is convenient to adjust processing specifications and various public parameters

The Product Parameters

Item | Parameter |

Suitable for H Beam | |

Flange width | 200-800mm |

Flange thickness | 6-25mm |

Web height | 200-1800mm |

Web thickness | 6-16mm |

H beam length | 2000-12000mm |

Welding Form | Double Wire Fillet Welding |

Welding speed | 100-1200mm (adjustable) |

Customer Site

Corporate Headquarters:

2477 Qizhou Road, Jinan, P.R.China