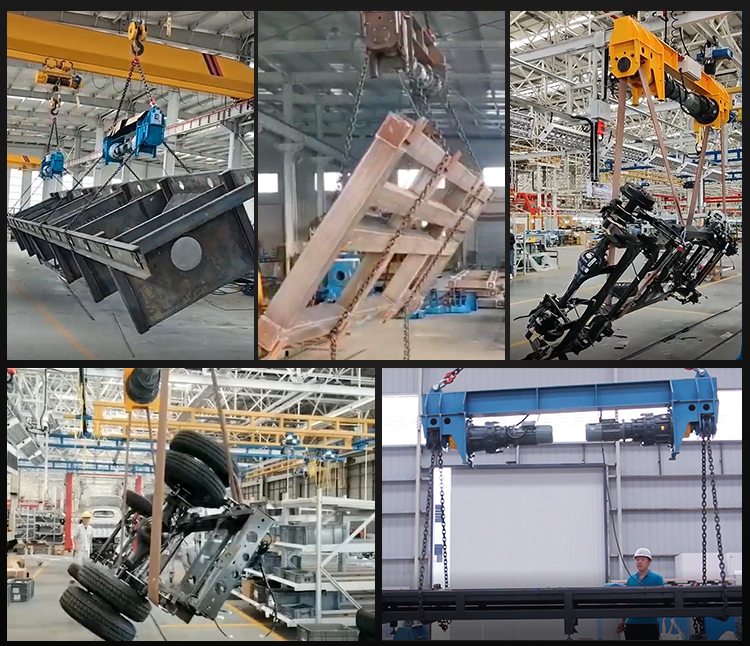

Chain Rotator Machine,used for the turning and short-distance lifting of complex heavy-duty steel structural parts;

When manufacturing heavy or complex components, steel structure enterprises often face problems like low turnover efficiency, high risk and surface damage of components. Our company’s chain turn-over machine can solve the above problems well.

Machine weight:1T, Macine size:2730*330*1300mm

YM-LFZ Series Chain Rotator Machine:

Use:Used for the turning and short-distance lifting of complex heavy-duty steel structural parts;

Chain Beam Rotator Features:

a. Remote control operation (easy to learn)

b. Stable operation, no skidding and no inversion when overturning large components

c. The turning angle is adjustable and can be turned 360°.

d. High security.

Max. lifting:10T;

Max. turn over Size (Section):1500mm*1500mm

Max. Turn over length:≤15M

turn over Speed:4000mm/min

Chain Beam Rotator Advantage:

1.360 degree barrier-free flip;

2. It can be flipped without being restricted by the length, width, size and shape of object;

3. The operation is simple and easy to master;

4. Stable operation, high safety factor and high turnover efficiency;

5. When the workpiece are turned over, the chain turning will cause less damage to the hoisting sling;

6. There is no damage to workpiece, and it is not easy to bump;

7. Use remote control to operate, the operator can stay away from the object during operation.

Beam Rotator is used for lifting and turning over large objects in industries such as stone processing, electric power, ships, docks, machinery manufacturing steel structures, etc.

Technical parameters

Name | Model | Unit | Note |

Machine dimensions | 2730*330*1300 | mm | Can be customized |

Motor Power | 2.2*2 | kw | |

Electric power source | 380 | v | |

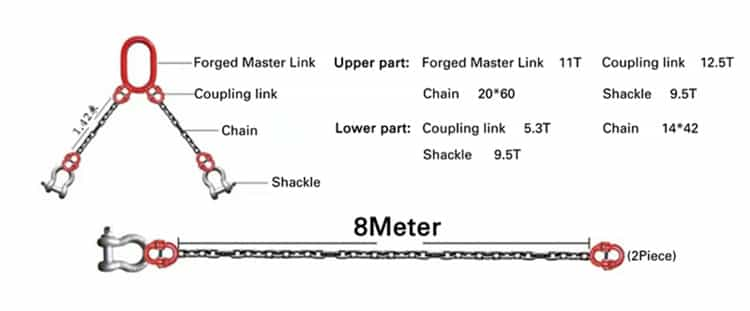

Lifting strap length | 8m*2 | m/piece | Can be customized |

Insurance factor | 1.2 | times | |

Remote control battery | 7#*2 | pieces | |

Flip angle | 360° | degree | Can be customized |

Max. lifting: | 10 | T | |

Max. turn over Size (Section):

| 1500*1500 | mm | |

Max. Turn over length:

| ≤15 | M | |

Flip Speed:

| 4000 | mm/min |

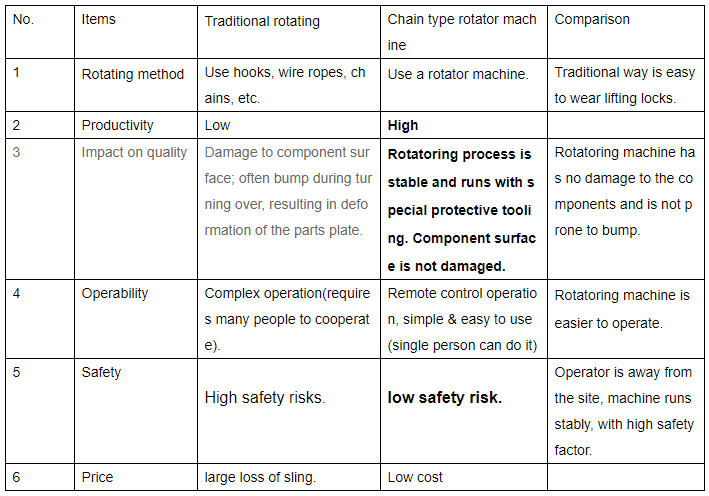

Advantages compare with traditional device

Rotator machine VS Traditional method | ||

Content | Rotator machine | Comparision |

Turning method | Rotator machine | Use hooks, wire ropes, chains, etc. |

Production efficiency | High Productivity | Low Productivity |

Impact on quality | Rotating process is stable and runing with special protective tooling. Component surface is not damaged. | Damage to component surface; often bump during rotating, resulting in deformation of the profile. |

Operability | Remote control operation, simple & easy to use (single person can do it) | Complex operation(requires many people to cooperate). |

Safety | Low risks | High risks. |

Usage cost | Low cost | large consumption of sling. |

Corporate Headquarters:

2477 Qizhou Road, Jinan, P.R.China